- Products

- Air Compressors & Air Tools

- Climate Control

- Compaction Equipment

- Concrete Cutting Tools & Equipment

- Concrete and Masonry

- Demolition & Excavation

- Electrical & Mechanical

- Fasteners and Anchoring Adhesives

- Floor Protection

- Generators and Welders

- Hand Tools

- Heaters

- Janitorial and Office Supplies

- Jobsite Protection

- Ladders & Storage

- Lighting & Lighting Accessories

- Man Lifts

- Material Handling Equipment

- Power Tools

- Pressure Washers & Pumps

- Safety Gear

- Safety Products

- Saws

- Surface Preparation

- SEASONAL PRODUCTS

- Rentals

- Air Compressor and Air Tool Rentals

- Climate Control Rental

- Compaction Rentals

- Concrete Equipment Rentals

- Demolition & Excavation Equipment Rentals

- Concrete Floor Grinder Rentals

- General Construction Equipment Rentals

- Generator Rentals and Welder Rentals

- Heater Rentals

- Light Tower Rentals

- Man Lift Rentals in Massachusetts and Rhode Island

- Material Handling Equipment Rentals

- Pressure Washer & Pump Rentals

- Saw Rentals in New England

- SEASONAL PRODUCTS

- Products

- Air Compressors & Air Tools

- Climate Control

- Compaction Equipment

- Concrete Cutting Tools & Equipment

- Demolition & Excavation

- Electrical & Mechanical

- Floor Protection

- Generators and Welders

- Construction Heaters

- Construction Ladders, Staging, & Storage

- Construction Lighting

- Man Lifts

- Material Handling Equipment

- Industrial Janitorial and Office Supplies

- Pressure Washers & Pumps

- Construction Safety Products

- Construction Safety Gear

- Surface Preparation

- Building Protection

- Diesel Accessories

- Zero Emissions

- Rentals

- Air Compressor and Air Tool Rentals

- Climate Control Rental

- Compaction Rentals

- Concrete Equipment Rental

- Demolition & Excavation Equipment Rental

- General Construction Equipment Rental

- Generator Rentals and Welder Rentals

- Construction Heaters Rental

- Light Tower Rentals

- Man Lift Rentals

- Material Handling Equipment Rental

- Pressure Washer & Pump Rentals

- Saw Rentals in New England

- Concrete Floor Grinder Rentals

- Zero Emissions Rentals

- Repairs & Used

- Parts

- Blog

- Services

- Resources

- About Us

- Contact Us

Sales & Rental of Construction | Industrial Equipment & Supplies

You are here:

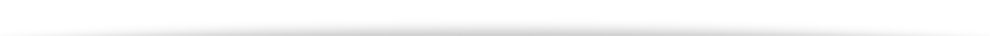

What are Machine Tools and How Do They Work?

Machine tools play a pivotal role in modern manufacturing. These are powerful machines that shape, cut, and finish materials with precision. They have transformed industries, enhancing productivity and efficiency.

The essence of machine tools lies in their design and function. Each tool is engineered for specific tasks, from drilling to milling. Yet, this specialization can be a double-edged sword. While it allows for intricate designs, it also means high costs and limited versatility.

Understanding machine tools is crucial for anyone in manufacturing. They are not just metal shavers; they represent innovation and technology. Despite their prowess, they can be complex and challenging to operate. Users must be trained and skilled, as mistakes can be costly. The future of machine tools holds promise but also demands reflection on how we adapt.

Table of Contents

[Hide]

What Are Machine Tools: Definition and Overview

Machine tools are essential devices used in manufacturing. They change the shape of materials through cutting, grinding, or drilling. These tools help in producing precise components for various industries. They can be operated manually or through computerized systems. The level of automation can significantly affect productivity and precision.

There are various types of machine tools, like lathes and milling machines. Lathes rotate the material against a cutting tool. This generates smooth surfaces and complex shapes. Milling machines use rotary cutters to remove material in multiple directions. Each type has its unique applications, strengths, and weaknesses. Yet, mastering them often requires skill and experience.

Not every machine tool yields flawless results. Operators may face challenges like tool wear or improper settings. Such errors can lead to wasted material and time. Understanding the nuances of each tool is vital for improvement. Continuous learning from mistakes often drives innovation and efficiency in the manufacturing process.

Machine Tools Usage by Type in Manufacturing

Types of Machine Tools: An In-Depth Look at Common Types

Machine tools are essential for shaping and cutting materials in various industries. They come in many forms, each serving a specific purpose. Lathes, milling machines, and grinders are among the most common types. A lathe allows for rotation and precision shaping of materials. It's often used to create cylindrical parts with great accuracy.

Milling machines, on the other hand, remove material using rotating cutting tools. They excel in creating complex shapes and features on a workpiece. Unlike lathes, mills can move both vertically and horizontally. Grinders, though simple in function, offer the precision needed for finishing parts to exact specifications. They are crucial for achieving smooth surfaces and tight tolerances.

It's worth noting that the operation of these tools requires skill and attention. Even minor errors can lead to defects in the final product. Operators must be diligent in maintaining equipment to ensure consistent quality. Sometimes, the learning curve can be steep. Each tool demands understanding and practice. Overlooking safety measures during operation can lead to hazardous situations. Machine tools serve as the backbone of manufacturing, yet they come with challenges that need to be tackled carefully.

What are Machine Tools and How Do They Work?

| Type of Machine Tool | Description | Common Uses | Working Principle |

|---|---|---|---|

| Lathe | A machine tool that rotates a workpiece to shape it. | Turning, facing, and drilling. | Removes material by cutting it away with a stationary tool. |

| Milling Machine | Uses rotary cutters to remove material from a workpiece. | Creating complex shapes and features. | Cuts using a rotating cylindrical tool that moves across the workpiece. |

| Drill Press | A stationary machine for drilling holes in various materials. | Drilling holes with precision. | Uses a rotating drill bit that cuts into the material. |

| Surface Grinder | A machine that uses a grinding wheel to create a smooth surface. | Finishing metal parts. | Removes material using a rotating grinding wheel for fine finishing. |

| CNC Machine | Computer-controlled machines for precise manufacturing. | High precision machining and mass production. | Uses programmed instructions to automate machining processes. |

The Mechanics of Machine Tools: How They Operate

Machine tools are essential in manufacturing. They help shape and cut materials into desired forms. Understanding their mechanics is important. Each machine tool operates on physical principles, allowing precise manipulation of materials.

The core mechanics involve motion and force. A spindle rotates a cutting tool. This rotation interacts with the workpiece, creating shapes. Tension and pressure control material removal. Often, the alignment of components determines the quality of a product. Small errors in setup can lead to major flaws.

Hydraulic or pneumatic systems may assist in movement. They provide additional power, helping to handle heavier materials. These systems, however, require maintenance. If neglected, they can cause malfunctions. Precision is key but not always easy to achieve. There’s a constant balance between speed and accuracy, which can be challenging.

Applications of Machine Tools in Various Industries

Machine tools play a vital role in numerous industries. These precision devices shape and finish materials. In manufacturing, they cut metals and plastics for a variety of products. They are often used to create parts for automobiles and electronics. However, not all machine tools perform perfectly every time. Minor errors in setup can lead to issues with dimensions.

In woodworking, machine tools help carve intricate designs. They're essential for creating furniture and cabinetry. Yet, craftsmanship can suffer if operators rush through processes. Some projects end up with uneven finishes, which can be frustrating. The same principle applies to construction. Here, accuracy is crucial, but tools may require adjustments. Underestimating this can lead to costly mistakes and rework.

The medical industry also relies on machine tools for precision components. Surgical instruments must meet exact specifications. However, failure in calibration can compromise quality. This highlights the importance of training and maintenance. Emphasizing attention to detail can enhance outcomes. Overall, machine tools are indispensable, but continuous reflection and improvement are essential for success.

Evolution of Machine Tools: Historical Development and Innovations

The history of machine tools is a fascinating journey through time. Early tools were simple yet effective. They laid the foundation for modern innovation. Hand tools were replaced by powered devices in the late 18th century. This marked a significant shift in manufacturing processes. The industrial revolution brought steam power into the mix. Suddenly, production rates soared. However, with such changes came challenges. Workers had to adapt quickly, facing both job loss and new opportunities.

The 20th century saw further advancements. The introduction of computer numerical control (CNC) changed everything. Precision machining became a reality. This allowed for intricate designs previously thought impossible. Yet, it also led to a reliance on technology that some argue could reduce skill levels. The balance between human skill and machine efficiency remains a topic of debate. Each innovation brought both excitement and uncertainty. The evolution of machine tools reflects our desire for progress, yet it prompts reflection on the implications of such advancements.

Related Posts

-

Top Machine Tools for Precision Engineering You Need to Know About

-

Top 10 Essential Power Tools Every DIYer Needs in 2023

-

10 Essential Tips for Choosing the Right Construction Tools for Your Projects?

-

Top 10 Essential Contractor Tools Every Professional Needs Today?

-

2026 How to Use All Tools for Maximum Efficiency?

-

Best Concrete Finishing Tools You Need for a Perfect Smooth Finish

© Copyright - Pro Tool & Supply - Site by SVM E-Marketing Solutions - Sitemap

- Privacy policy